Commercial infrastructure shapes how people work, move, and do business every day. Offices, medical centers, warehouses, and mixed-use buildings all fall into this space. Behind these structures is a long chain of planning, coordination, and execution. Engineering construction firms play a central role in that process.

MPS Engineering & Construction operates within this environment. Not as a concept, but as a working participant in real projects. Understanding how such firms shape commercial infrastructure helps explain why some projects run smoothly while others struggle..

What Commercial Infrastructure Really Involves

Commercial infrastructure is not just about putting up walls and roofs. It includes site preparation, utilities, structural systems, safety planning, and long-term usability.

Each project begins with constraints.

The site has limits.

The budget has limits.

The schedule has limits.

Engineering construction firms work within those boundaries. Their job is to make the project functional, safe, and durable despite those limits.

This is where experience matters. A plan that looks fine on paper may behave very differently once work begins.

Early Project Stages Shape Everything

Most outcomes are decided before construction starts. This phase often receives less attention, but it carries the most weight.

Engineering teams review drawings and technical details. They assess soil reports, drainage paths, and access points. They look for risks that could cause delays later.

Small adjustments at this stage prevent large problems later.

Changing a foundation detail early costs little.

Fixing it after construction begins costs much more.

This early involvement influences how predictable the project becomes.

Translating Design Into Reality

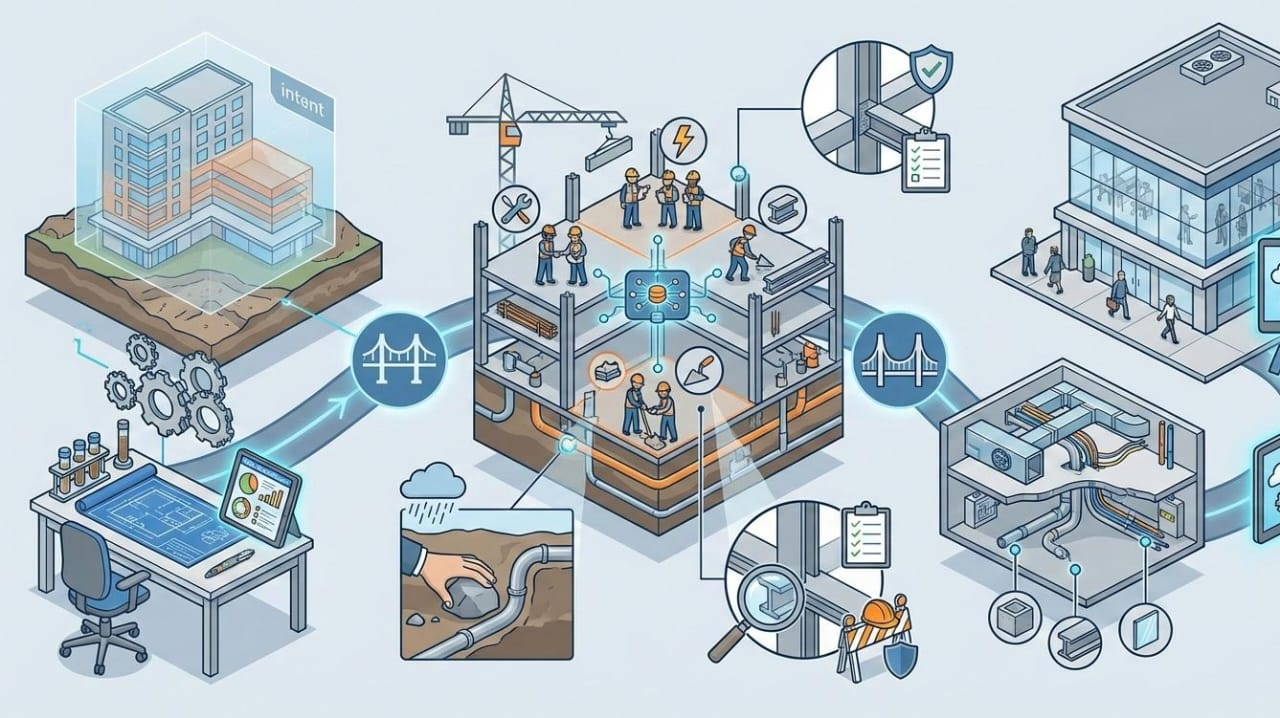

Architectural designs show intent. Construction turns intent into reality. The gap between the two is where engineering construction firms operate.

Not every design detail translates cleanly to real materials or site conditions. Engineering teams adjust methods without changing core intent. This keeps the project aligned with original goals while staying practical.

Clear translation reduces confusion on site.

It also prevents rework.

When this step is handled well, construction flows more smoothly.

Managing Multiple Trades at Once

Commercial sites are busy places. Electricians, plumbers, steel crews, and concrete teams often work at the same time.

Engineering construction firms coordinate this movement.

They sequence tasks.

They resolve conflicts before they become delays.

Poor coordination leads to idle time.

It also increases safety risks.

Good coordination keeps momentum steady and predictable.

Responding to Real Site Conditions

No site behaves exactly as expected. Weather shifts. Materials arrive late. Soil conditions vary across short distances.

Engineering teams adjust plans in response. They do not rely on rigid assumptions. They observe and adapt.

This flexibility keeps work moving.

It also protects structural performance.

Experience helps here. Teams that have seen similar issues before respond faster and with more confidence.

Quality Control Happens Every Day

Quality is not a final step. It is ongoing.

Engineering checks happen throughout construction.

Before concrete pours.

Before framing is closed.

Before systems are sealed.

These checks catch small issues early. Fixing them early avoids larger problems later.

Quality control also supports compliance. Buildings must meet codes and standards at every stage, not just at inspection.

Safety as a Daily Practice

Commercial construction carries real risks. Heavy equipment, heights, and confined spaces are common.

Engineering construction firms plan safety into daily operations. Clear procedures reduce accidents. Predictable workflows protect workers.

Safety planning also affects schedules. Accidents slow projects down. Preventing them keeps timelines intact.

This is a practical concern, not just a regulatory one.

Navigating Regulations and Inspections

Commercial projects must meet many regulations. Local codes. State rules. Federal standards.

Engineering construction firms manage this complexity. They prepare documentation. They coordinate inspections. They address corrections when needed.

Regulatory alignment is not optional.

Missing a requirement can halt progress.

Clear documentation and early coordination reduce friction with authorities.

Material Choices Affect Long-Term Performance

Material selection influences how a building ages. Some choices reduce maintenance. Others increase durability.

Engineering teams evaluate these trade-offs during construction. They consider cost, availability, and performance.

Short-term savings can create long-term issues.

Balanced decisions support stable operations over time.

This perspective is critical for commercial buildings meant to last decades.

Systems Integration Matters

Modern commercial buildings rely on systems. HVAC, electrical, data, and plumbing must work together.

Engineering construction firms coordinate this integration. Poor coordination leads to inefficiencies and service issues later.

Good integration supports comfort, energy efficiency, and reliability.

This is often invisible to occupants, but it defines their experience.

Documentation Supports Future Use

Once construction ends, documentation remains. Drawings, manuals, and records support future maintenance and upgrades.

Engineering construction firms organize this information. Clear records help facility managers understand the building.

Missing documentation creates confusion years later.

Complete records support long-term value.

This aspect is often overlooked, but it matters.

Adapting to Changing Standards

Construction standards evolve. New materials appear. Methods improve. Regulations change.

Engineering construction firms adjust their practices. They update workflows and retrain teams.

This adaptation keeps projects aligned with current expectations.

It also improves safety and efficiency.

Static practices fall behind. Adaptive ones stay relevant.

Collaboration With Stakeholders

Commercial infrastructure involves many stakeholders. Owners, designers, inspectors, and end users all have input.

Engineering construction firms act as connectors. They translate technical issues into practical terms.

Clear communication prevents misunderstandings.

It also builds trust.

Strong collaboration keeps projects aligned with shared goals.

Why Process Outweighs Branding

Infrastructure quality comes from systems, not slogans.

Planning discipline.

Technical judgment.

On-site awareness.

These factors shape outcomes more than names or claims.

Industry observers often focus on how firms work rather than what they say. That approach reveals the real drivers of success.

The Broader Impact on Commercial Environments

Well-executed infrastructure supports business activity. Employees work more comfortably. Operations run smoothly. Maintenance costs stay manageable.

Poorly executed projects create friction. Repairs increase. Systems fail sooner.

Engineering construction firms influence which path a project follows. Their decisions ripple outward over time.

Final Perspective

Commercial infrastructure is built through many quiet decisions. Most are unseen. All are important. MPS Engineering Construction operates within this reality. Through planning, coordination, and execution, such firms shape how commercial spaces function long after construction ends.

Understanding this process offers insight into why some buildings perform better than others. It is not about promotion. It is about practice.